-

Proma’s S & M Series Roll Grinder are designed to be heavy duty OD grinders capable of grinding high rollers up to 4 tons, to be used in high precision industries such as Aircraft Landing Gear MRO, Paper & Steel Roller production & Repairs.

PROMA M Type

PROMA M TypeSize to Medium size Heavy Duty OD Roll Grinder with option CNC, NC or Manual control.

Item PROMA S40 PROMA M60 Max Swing over Table Ø400mm Ø600mm Max Distance between Center 1.5M,2M,3M,4M 3M,4M,5M,6M Max Workpiece Weight 1,500 KG 4,000 KG Max OD Diameter Ø400mm Ø600mm Wheel Size (OD x Width x Bore) Ø500 x 152.4 x 50mm Ø910 x 304.8 x 75mm Grinding Wheel RPM 300 – 1,800 RPM 300 – 1,200 RPM Grinding Wheel Cross Feed Rate 1000mm/min 1000mm/min Table Travel Speed 25 – 3000mm/min 25 – 6000mm/min Work Head Rotation 10 – 100 RPM 8 – 80 RPM Center Taper MT#5 MT#6 Quill Stroke 50mm 80mm Grinding Wheel Motor 15 HP 20HP -

- Machine Casing – The table/headstock, machine base, and carriage are all made of high strength FC-30 – FC-35 castings. The guideways are constantly being lubricated by a hydrodynamic hydrostatic lubrication system to reduce drag between components and improve part finish.

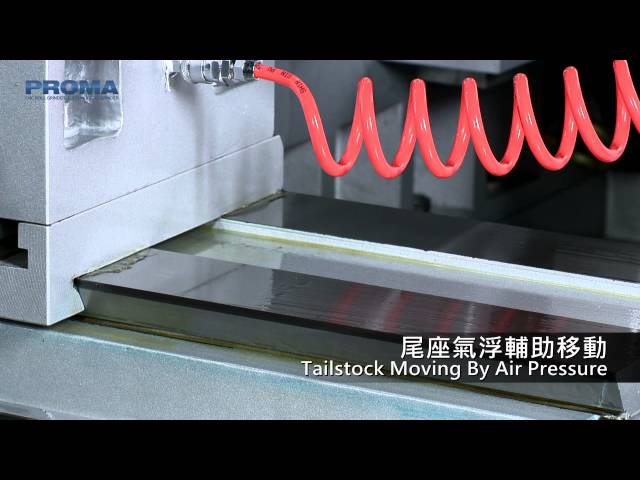

- Tail stock – Tailstock re-positioning is made easy thru the use of an air assist device mounted on the bottom of the tailstock. Work piece alignment is done via tailstock adjustment. The diamond wheel dresser is mounted on side of the tailstock for easy access. An optional revolving 4-jaw chuck tailstock is available for extremely heavy workpieces.

- Wheel Head – The wheelhead spindle is designed with hydrodynamic bearing and is made of Ni-CR-Mo alloy for superior strength and maximum grinding finish. The wheelhead and carriage are lubricated by a hydrodynamic & hydrostatic lubrication system. The spindle and spindle motor utilize an indirect design to avoid strain on the motor.

- Headstock – Headstock RPM is infinitely variable thru use of a frequency motor. Re-positioning is made easy using an air assist devise mounted on the bottom of the wheelhead. A spring driven trip dog is used to ensure a smooth start up and rotation of the workpiece. S40 & M60 models use live and dead centers. The L85 uses a rotating center.

- CNC Controller – The FANUC CNC-controller provides a more automated roll grinding process where the grinding operator inputs a grinding program to performed the grinding cycle sequentially. The crown grinding is also easy to get which include base arc curve SINE curve COSINE curve CVC curve and combined arc curve. The camber values are assigned by the program.

- Accessories – Proma grinders can be equipped with Automatic OD Measuring system for in cycle measuring.

-

Contact Us

ARE YOU INTERESTED IN THIS TECHNOLOGY?

Leave us a message and we will respond to you as soon as possible!