Unison manufactures nine versions of its Flexible Grinding System (FGS). Each of these machines use Unison’s proprietary software and motion control. The FGS Series is constructed on a cast iron base which has been hand scraped to insure the highest level of accuracy. Precision ground ballscrews are installed to provide smooth motion control and increase both the accuracy and longevity of the FGS Series machines.

Click on the following tabs for more information:

-

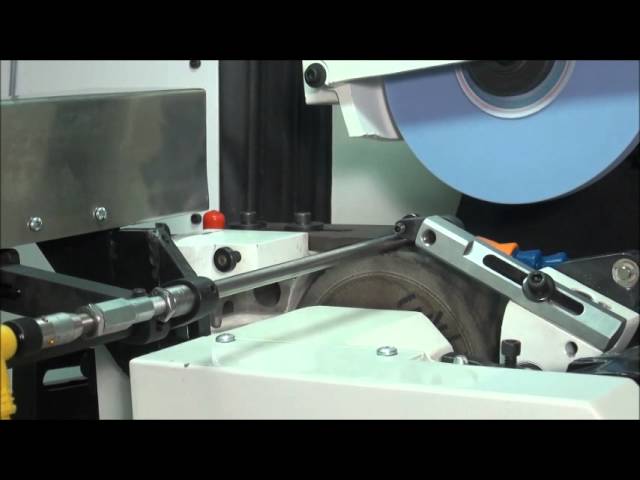

FGS Model 2150 is a precision 3 axis CNC grinding system for centreless OD grinding. The Model 2150’s are highly precise grinders for centerless OD grinding and are used for thrufeed, infeed and secondary operations such as plunge grinding, tapers and profile grinding for cylindrical parts with diameters from .005” 0 (.127mm) to 5” (127mm). This CNC Grinders are ideal for prepping blanks used in the manufacture of precision cutting tools.

-

Unison is pleased to introduce our latest Version software package which is designed specifically for automated Blank Preparation using our Model 2150 CNC DedTru® Grinding System. This Windows™ based software requires the operator to simply enter the basic tool characteristics of the shape to be ground and the machine’s control will automatically calculate the required wheel geometry, dressing locations and grinding parameters. The software calculates the required offsets and determines the best method for grinding the blank.

Since the Model 2150 is equipped with “In-Process” wheel dressing capability for conventional aluminum oxide and superabrasive grinding wheels, the machine practically runs itself. When equipped with Unison’s optional on-board Electric Dresser, the machine can also dress complex profiles in both diamond and CBN grinding wheels. Navigation of the software is easy using the 15” high-resolution touch screen display in the new, larger operator’s console.

-

Contact Us

ARE YOU INTERESTED IN THIS TECHNOLOGY?

Leave us a message and we will respond to you as soon as possible!